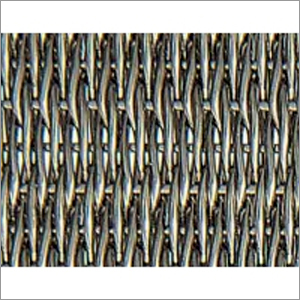

Paper Mill Wire Mesh

Paper Mill Wire Mesh Specification

- Wire Gauge

- 10 - 30 SWG

- Aperture

- 2mm - 8mm

- Hole Shape

- Rectangular

- Surface Treatment

- Galvanized

- Length

- 30 - 50 meters

- Product Type

- Industrial Wire Mesh

- Mesh Type

- Fine Mesh

- Mesh Style

- Woven / Welded

- Material

- Stainless Steel

- Alloy

- SS304, SS316

- Application

- Paper Mill, Pulp Filtration

- Dimensions

- Width 1m - 2m

- Wire Diameter

- 0.3mm - 3mm

- Weight

- As per Size

- Color

- Silver

- Tensile Strength

- High (suitable for industrial use)

- Open Area Percentage

- 18% - 50%

- Corrosion Resistance

- Excellent (especially stainless steel)

- Edge Finish

- Plain / Selvage Edge

- Operating Temperature

- Up to 350°C (depending on material)

- Customization

- Available for Mesh Size, Width, Length, Material

- Usage Life

- Long-lasting, Reusable

- Packing Type

- Rolls or Cut Lengths, Wrapped in Moisture-Proof Paper

Paper Mill Wire Mesh Trade Information

- Minimum Order Quantity

- 100 Square Foots

- Supply Ability

- 500 Square Foots Per Day

- Delivery Time

- 1-7 Days

About Paper Mill Wire Mesh

Offered Stainless Steel Mill Finish Netting has been designed as per ASTM norms. Notable for its square shaped holes, this type of net is used to develop machine guards, partition, sound enclosure, filters and screening materials etc. Special diameter of this product allows required penetration of air. Mill finished surface of this product is totally protected against wear, abrasion, corrosion and various damaging factors of environment. Simple to install, this type of netting solution can be maintained easily for its long lasting surface finish. Quality of offered steel item has been verified on the basis of its dimension, strength, resistant attributes and installation process. We are a growth oriented trader and supplier of premium grade Stainless Steel Mill Finish Netting.

Product Details

Width | 1 m,3 feet,4 feet |

Usage/Application | Rice Mill |

Material Grade | SS202,SS304,SS316 |

Roll Length | 15 m,30 m |

Brand | Safety Mesh |

Material | SS |

High Performance & Customization

Our Paper Mill Wire Mesh stands out for its exceptional durability, high tensile strength, and adaptability to numerous industrial filtration requirements. With customizable dimensions, mesh types, and material grades, users can select a solution best suited to their applicationensuring optimal performance and efficiency across projects.

Excellent Corrosion Resistance & Longevity

Manufactured primarily from high-grade stainless steels such as SS304 and SS316, this mesh offers outstanding resistance to corrosioneven under harsh operating conditions. The robust construction paired with appropriate surface treatments, such as galvanizing, means superior longevity and reliable reusability for multiple filtration cycles.

Versatile Applications in Pulp & Paper Industry

Designed for use in paper mills and pulp processing, these wire meshes effectively filter and separate materials in demanding industrial environments. Their adjustable open area and mesh style options ensure precise filtration for diverse operational needs, enhancing overall productivity and process reliability.

FAQs of Paper Mill Wire Mesh:

Q: How can I customize the Paper Mill Wire Mesh for my specific application?

A: You can customize this mesh by selecting your preferred mesh size, width (1m-2m), length (30m-50m), material type (SS304, SS316), wire gauge (10-30 SWG), aperture size (2mm-8mm), wire diameter (0.3mm-3mm), and mesh style (woven, welded, fine). Reach out with your filtration requirements, and our team will assist in tailoring the product to your process.Q: What are the benefits of using stainless steel wire mesh in paper mills?

A: Stainless steel grades SS304 and SS316 offer superior tensile strength, exceptional corrosion resistance, and the ability to withstand high temperatures (up to 350C depending on material). This ensures the mesh delivers long-lasting, reusable, and reliable performance even in harsh industrial environments.Q: When is it best to use wire mesh with a higher open area percentage?

A: Higher open area percentages (closer to 50%) are ideal when you require efficient filtration with minimal flow restriction. This is especially beneficial in pulp filtration processes where maximizing throughput and minimizing clogging are essential.Q: Where can Paper Mill Wire Mesh be applied beyond pulp and paper?

A: In addition to pulp and paper mills, this wire mesh is widely used in industries requiring fine filtration and separation, such as water treatment, food processing, mining, and chemical manufacturinganywhere durability and corrosion resistance are vital.Q: What is the process for ordering mesh in rolls versus cut lengths?

A: You may request the mesh in standard rolls (30m-50m lengths) or as customized cut lengths according to your project requirements. We ensure packing in moisture-proof paper to maintain quality during shipping and storage.Q: How does surface treatment like galvanization benefit the mesh?

A: Galvanizing adds an extra layer of corrosion protection, increasing the meshs lifespan in environments prone to moisture or chemical exposure. This is particularly useful for operations where long-term durability is critical.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wire Mesh Category

Filter Wire Mesh

Price 13000 INR / Square Foot

Minimum Order Quantity : 100 Square Foots

Length : Available in custom lengths

Surface Treatment : Other, Galvanized, PVC coated

Dimensions : Standard width: 1 m, 1.2 m, 2 m; Custom sizes available

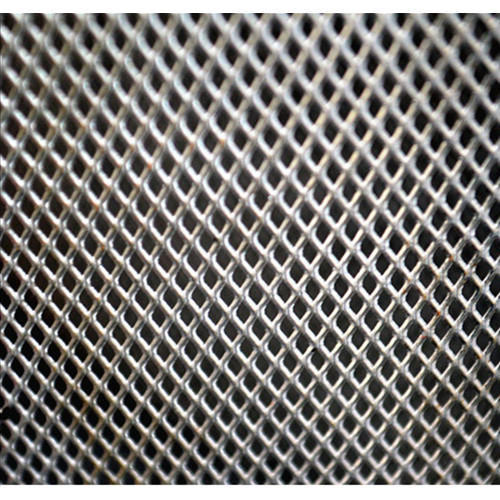

Diamond Wire Mesh

Price Range 40.00 - 400.00 INR / Square Foot

Minimum Order Quantity : 100 Square Foots

Length : 1530 Meter rolls

Surface Treatment : Other, Galvanized, PVC Coated

Dimensions : Height: 3ft, 4ft, 5ft, 6ft (customizable)

Steel Wire Mesh

Price Range 40.00 - 400.00 INR / Square Foot

Minimum Order Quantity : 100 Square Foots

Length : 1 m to 30 m (customizable)

Surface Treatment : Other, Galvanized / PVC Coated

Dimensions : Standard: 1 m x 15 m / 2 m x 30 m or as required

Super Duplex Stainless Steel Wire Mesh

Price 110 INR / Square Foot

Minimum Order Quantity : 100 Square Foots

Length : Variable

Surface Treatment : Polished

Dimensions : Customizable

Send Inquiry

Send Inquiry