Stainless Steel Welded mesh

Stainless Steel Welded mesh Specification

- Aperture

- 12.5 mm to 50 mm

- Surface Treatment

- Mill Finish

- Wire Gauge

- 12 to 24 SWG

- Length

- up to 30 meters per roll

- Hole Shape

- Square

- Product Type

- Welded Mesh

- Mesh Type

- Welded

- Mesh Style

- Welded Mesh

- Material

- Stainless Steel (SS304/316)

- Alloy

- SS304 & SS316

- Application

- Fencing, Construction, Industrial, Agriculture, Security

- Dimensions

- customizable, standard width: 900 mm - 2000 mm

- Wire Diameter

- 0.5 mm to 2.5 mm

- Weight

- varies by size and gauge, approx. 1 to 15 kg/m2

- Color

- Silver

- Packing Type

- Rolls or panels, wrapped with moisture-proof paper

- Welding Type

- Spot welding

- Edge Type

- Cut or folded edges

- Usage Environment

- Suitable for harsh and corrosive environments

- Temperature Resistance

- Up to 800°C

- Tensile Strength

- 350-550 N/mm²

- Corrosion Resistance

- Excellent, suitable for outdoor use

Stainless Steel Welded mesh Trade Information

- Minimum Order Quantity

- 100 Square Foots

- Supply Ability

- 500 Square Foots Per Day

- Delivery Time

- 1-7 Days

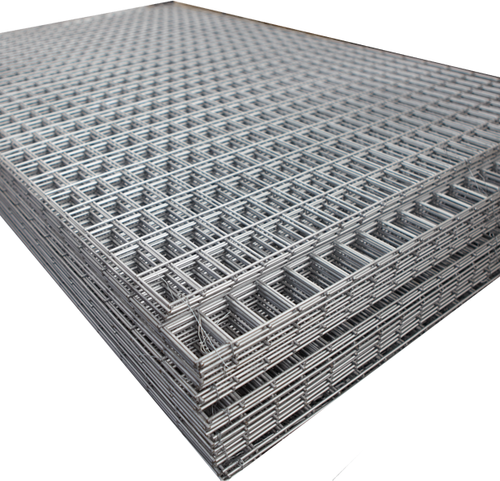

About Stainless Steel Welded mesh

The offered Stainless Steel Welded mesh is made available by us for use in the various commercial and industrial applications. The welded wire mesh is a metal wire screen that is made up of low carbon steel wire or stainless steel wire. It is widely used in agricultural, industrial, transportation, horticultural and food procuring sectors. It is also used in mines, gardening, machine protection and other decorations. It an electric fusion welded prefabricated joined grid consisting of a series of parallel longitudinal wires with accurate spacing welded to cross wires at the required spacing. The Stainless Steel Welded mesh is very durable and useful.

Product specifications

Color | Silver |

Material Grade | SS304 |

Brand | Safety Mesh |

Usage/Application | Agricultural |

Weave Type | Square |

Wire Diameter | 2.6 mm |

Country of Origin | Made in India |

Width | 1 m |

Size of Opening | 10.06 mm |

Material | Stainless Steel |

Length | 30 m |

Engineered for Extreme Conditions

This stainless steel welded mesh stands out with its superior corrosion resistance and ability to withstand temperatures up to 800C. Suitable for harsh, corrosive, and outdoor environments, it is engineered to deliver long-lasting performance where conventional materials fall short. The spot-welded construction adds strength and stability for industrial and security applications.

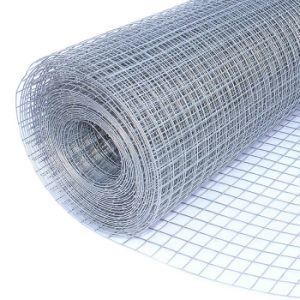

Flexible Dimensions and Applications

Available in both rolls and panels, the welded mesh can be customized for length, width, and wire gauge, adapting to various project requirements. With wire diameters from 0.5 mm to 2.5 mm and apertures between 12.5 mm and 50 mm, it suits uses in fencing, construction, agriculture, and industrial settings. Standard widths range from 900 mm to 2000 mm, offering flexibility for installers and designers.

Assured Quality and Easy Handling

Produced with mill finish and supplied in a silver color, each mesh is meticulously packed with moisture-proof paper to safeguard against environmental wear during transport or storage. The choice of cut or folded edges and robust tensile strength ensures safe, easy installation and dependable structural integrity, supporting demanding professional environments.

FAQs of Stainless Steel Welded mesh:

Q: How is the corrosion resistance of this stainless steel welded mesh ensured?

A: The mesh is constructed from high-quality SS304 and SS316 stainless steel, both known for their outstanding corrosion resistance. This makes it suitable for outdoor, harsh, or corrosive environments, ensuring longevity and minimal maintenance.Q: What applications is this welded mesh suitable for?

A: It is widely used in fencing, construction, industrial settings, agriculture, and security due to its strong welded structure, high tensile strength, and resilience to corrosion and temperature extremes.Q: When should I choose between cut or folded edges for the mesh?

A: Select cut edges for a standard finish or where the mesh is framed, and folded edges for enhanced safety and smoothness, especially in applications where exposed wires could cause injury or snags.Q: Where can this welded mesh be installed for optimal performance?

A: It is ideal for installation in outdoor areas, corrosive industrial zones, agricultural fields, and construction sites, thanks to its resistance to rust and ability to withstand varied and harsh environmental conditions.Q: What is the manufacturing process for this type of welded mesh?

A: The mesh is produced through spot welding, where stainless steel wires (12 to 24 SWG, 0.5 mm to 2.5 mm) are joined at intersections, ensuring strong, uniform bonds. This method delivers enhanced strength for diverse heavy-duty uses.Q: How should the mesh be stored and handled before installation?

A: Each mesh roll or panel is wrapped with moisture-proof paper, protecting it from moisture and contamination during transport and storage. Store in a dry, covered area until ready for use to maintain its quality.Q: What are the benefits of using this mesh in construction and security?

A: Its high tensile strength, temperature tolerance up to 800C, and superior corrosion resistance offer reliable protection and long-term value, reducing replacement frequency and enhancing safety in demanding projects.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Welded Mesh Category

GI Welded Mesh

Price Range 40.00 - 400.00 INR / Square Foot

Minimum Order Quantity : 100 Square Foots

Weight : Approx. 30 kg per roll

Wire Diameter : 2.5 mm

Mesh Type : Other , Square / Rectangular Mesh

Dimensions : 1 m x 25 m (standard roll size)

Mild Steel Weld Mesh

Price Range 40.00 - 400.00 INR / Square Foot

Minimum Order Quantity : 100 Square Foots

Weight : As per size and specification

Wire Diameter : 0.56 mm to 4.06 mm

Mesh Type : Other , Welded

Dimensions : Width: 0.5 m to 2.5 m or customized

Spring Steel Wire Mesh

Price Range 40.00 - 400.00 INR / Square Foot

Minimum Order Quantity : 100 Square Foots

Weight : As per size & thickness

Wire Diameter : 0.5 mm 2.5 mm

Mesh Type : Other , Wire Mesh

Dimensions : Standard and customizable (e.g. 1 x 5 m, 1.2 x 2.4 m)

Welded Mesh Sheets

Price Range 40.00 - 400.00 INR / Square Foot

Minimum Order Quantity : 100 Square Foots

Weight : Variable, depends on gauge and size

Wire Diameter : 1.2 mm to 2.8 mm

Mesh Type : Other , Sheet Mesh

Dimensions : 2400 mm x 1200 mm (standard), customizable

Send Inquiry

Send Inquiry