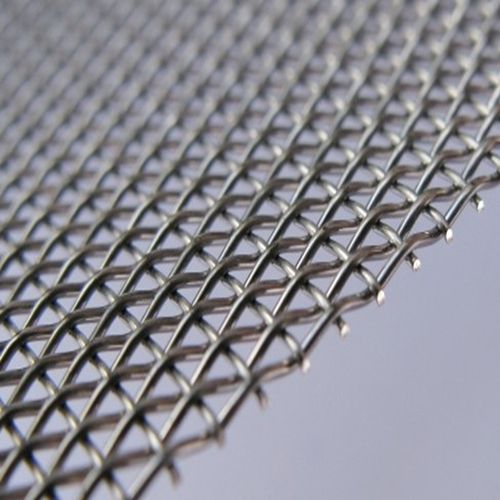

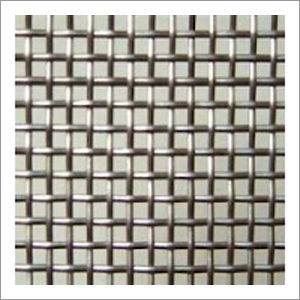

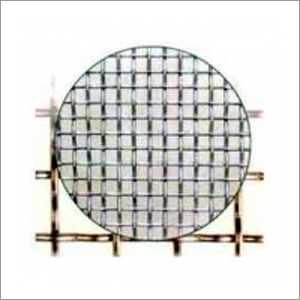

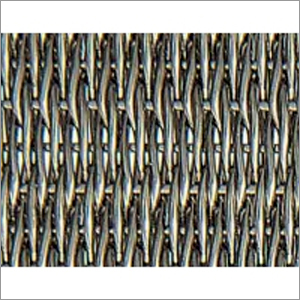

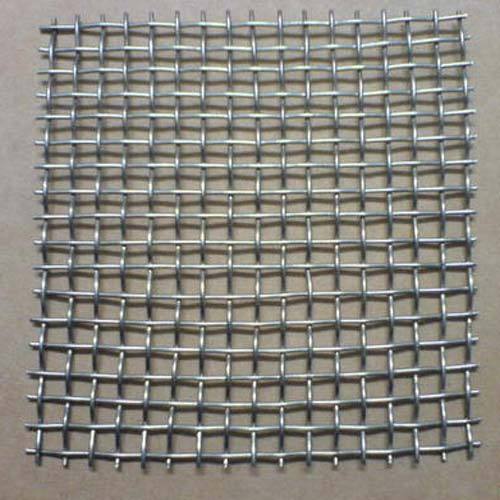

304/316 Plain Weave Stainless Steel Wire Mesh

304/316 Plain Weave Stainless Steel Wire Mesh Specification

- Hole Shape

- Square

- Surface Treatment

- Mill finish, polished or as required

- Wire Gauge

- 12 SWG to 36 SWG

- Length

- 15 m, 30 m, or customized

- Aperture

- 0.025 mm 12 mm

- Product Type

- Wire Mesh

- Mesh Type

- Woven Mesh

- Mesh Style

- Plain Weave

- Material

- 304/316 Stainless Steel

- Alloy

- SS 304, SS 316

- Application

- Filtration, sieving, protection, reinforcement

- Dimensions

- Width: 1 m, 1.2 m, 1.5 m or customized

- Wire Diameter

- 0.020 mm 2.1 mm

- Weight

- Depends on mesh and wire diameter

- Color

- Silver

- Temperature Resistance

- Up to 800°C

- Standards

- ASTM, ISO

- Edge Type

- Plain / Selvage Edge

- Width

- 0.5 m to 2 m (customizable)

- Packing

- Rolls wrapped in moisture-proof paper or plastic

- Corrosion Resistance

- Excellent

- Tensile Strength

- High

- Pattern

- Plain weave with consistent mesh opening

304/316 Plain Weave Stainless Steel Wire Mesh Trade Information

- Minimum Order Quantity

- 100 Square Foots

- Supply Ability

- 500 Square Foots Per Day

- Delivery Time

- 1-7 Days

About 304/316 Plain Weave Stainless Steel Wire Mesh

304-316 Palin Weave Stainless Steel Wire Mesh is widely designed and manufactured by making use of premium grade of stainless steel materials. This wire mesh can be made up of a variety of crimping patterns for the interlocking segments. Our wire mesh is employed in security guarding and as vandal protection in the form of vandal screens. 304-316 Palin Weave Stainless Steel Wire Mesh is very cost effective and can be easily availed at nominal rates, by our valued customers, in bulk quantities.

Product specifications

Color | Silver |

Material Grade | SS304 |

Brand | Safety Mesh |

Usage/Application | Construction |

Country of Origin | Made in India |

Width | 2 m |

Thickness | 50 mesh |

Packing Type | Roll |

Material | Stainless Steel |

Length | 15 m |

Superior Corrosion and Temperature Resistance

Constructed from 304 or 316 stainless steel alloys, the wire mesh is highly resistant to rust, oxidation, and adverse chemicals. Its ability to endure temperatures up to 800C makes it reliable for harsh and high-temperature environments.

Versatile Customization for Multiple Uses

With customizable widths, lengths, and mesh openings, this wire mesh can be tailored for a wide range of industries. From fine filtration and sieving to robust protection and reinforcement, its adaptability is a key advantage.

Certified Quality and Material Integrity

Manufactured in adherence to ASTM and ISO standards, each mesh guarantees precision, consistency, and premium quality. The plain weave offers uniform aperture distribution for dependable performance in demanding applications.

FAQs of 304/316 Plain Weave Stainless Steel Wire Mesh:

Q: How does stainless steel wire mesh resist corrosion in challenging environments?

A: 304/316 stainless steel contains chromium and nickel, which form a protective oxide layer on the surface, giving the mesh excellent resistance to rust, oxidation, and various corrosive agents even when exposed to moisture or chemicals.Q: What process is used to manufacture the plain weave stainless steel wire mesh?

A: The mesh is woven using a plain weaving technique wherein each wire crosses alternately over and under the wires at right angles, generating a tight and uniform mesh structure ideal for stable and precise filtration.Q: When should I choose 316 stainless steel over 304 for my mesh application?

A: Select 316 stainless steel if your mesh will be used in highly corrosive environments, such as marine or chemical processing settings, as it offers enhanced resistance due to its higher molybdenum content.Q: Where can this wire mesh be practically applied?

A: This stainless steel mesh is widely used in filtration systems, sieving and sorting equipment, architectural screening, safety fences, and reinforcement in construction or industrial processing.Q: What benefits does the plain weave pattern provide?

A: The plain weave creates consistent and precise mesh openings, ensuring reliable filtration and even support for sieving, protecting, or reinforcing duties, with strong tensile integrity.Q: How is the mesh typically packaged and delivered?

A: For protection during storage and shipping, the mesh is rolled and wrapped in moisture-proof paper or plastic, helping to preserve its finish and prevent contamination or damage.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wire Mesh Category

Plain Steel Wire Mesh

Price 54000 INR / Square Foot

Minimum Order Quantity : 100 Square Foots

Dimensions : Customized, Standard width up to 4 feet

Length : 30 meters

Wire Gauge : 12 to 30 SWG

Material : Other, Mild Steel, Stainless Steel

Refractories Wire Mesh

Price 500 INR / Square Foot

Minimum Order Quantity : 100 Square Foots

Dimensions : 1 m x 30 m, 1.2 m x 30 m

Length : Customizable up to 30 meters

Wire Gauge : 1020 SWG

Material : Other, Stainless Steel / Mild Steel

Filter Wire Mesh

Price 13000 INR / Square Foot

Minimum Order Quantity : 100 Square Foots

Dimensions : Standard width: 1 m, 1.2 m, 2 m; Custom sizes available

Length : Available in custom lengths

Wire Gauge : 1230 SWG

Material : Other, Stainless Steel (SS304, SS316), Mild Steel

SS Square Wire Mesh

Price 70 INR / Square Foot

Minimum Order Quantity : 100 Square Foots

Dimensions : Width: 1 m, 1.2 m, 1.5 m (custom sizes available)

Length : 30 meter rolls (custom available)

Wire Gauge : 14 to 22 gauge

Material : Other, Stainless Steel (SS304/SS316/SS316L)

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese