Refractories Wire Mesh

Price 500 INR/ Square Foot

Refractories Wire Mesh Specification

- Surface Treatment

- Galvanized

- Wire Gauge

- 10-20 SWG

- Length

- Customizable up to 30 meters

- Hole Shape

- Square

- Aperture

- 1 mm to 6 mm

- Product Type

- Refractories Wire Mesh

- Mesh Type

- Fine Mesh

- Mesh Style

- Woven

- Material

- Stainless Steel / Mild Steel

- Alloy

- SS304, SS316, MS

- Application

- Refractories lining, Furnace lining, Thermal insulation support

- Dimensions

- 1 m x 30 m, 1.2 m x 30 m

- Wire Diameter

- 0.9 mm to 2 mm

- Weight

- 2 kg to 10 kg/roll

- Color

- Silver

- Operating Temperature

- Up to 1200°C

- Fire Resistance

- Excellent

- Edge Type

- Plain / Selvedge

- Porosity

- Optimized for airflow control

- Usage

- Industrial, Construction

- Delivery Condition

- Ready to Use / As per specifications

- Customization

- Available

- Shape

- Roll

- Packing Type

- Rolls

- Tensile Strength

- High

- Corrosion Resistance

- High

Refractories Wire Mesh Trade Information

- Minimum Order Quantity

- 100 Square Foots

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID), Cheque

- Supply Ability

- 500 Square Foots Per Day

- Delivery Time

- 1-7 Days

- Sample Available

- Yes

- Main Domestic Market

- All India

About Refractories Wire Mesh

High-Temperature Reliability

Designed to withstand temperatures up to 1200C, this wire mesh is ideal for applications involving high heat, such as refractories and furnace lining. Its fire resistance ensures prolonged operational life and safety in thermal insulation support systems.

Optimized Airflow & Structural Strength

The wire mesh is engineered with controlled porosity, allowing for efficient airflow management within industrial settings. High tensile strength and woven fine mesh styles provide robust support while meeting specific construction and lining needs.

Customizable and Ready for Use

Available in standard sizes and customizable lengths up to 30 meters, the mesh comes in galvanized silver finish, with both plain and selvedge edge options. Ready-to-use delivery and tailored specifications offer flexibility for diverse industrial requirements.

FAQs of Refractories Wire Mesh:

Q: How is Refractories Wire Mesh used in industrial and construction applications?

A: Refractories Wire Mesh supports refractories lining, furnace lining, and thermal insulation systems, providing structural integrity, airflow control, and fire resistance in demanding industrial environments.Q: What materials and surface treatments are available for this wire mesh?

A: The mesh is manufactured from stainless steel (SS304, SS316) or mild steel, and features a galvanized surface treatment for enhanced corrosion resistance and long-term durability.Q: When should I choose a wire mesh with customized dimensions or specifications?

A: Customized mesh is recommended when standard size or design does not fit your specific application, such as for unique furnace sizes, specialized airflow control, or tailored tensile strength requirements.Q: Where can this mesh be applied for maximum benefit?

A: Its optimal performance is observed in high-temperature areas like furnace linings, refractories lining, and thermal insulation support in industrial facilities, construction projects, and heavy machinery housing.Q: What is the process for ordering customized wire mesh specifications?

A: You can specify required wire gauge (10-20 SWG), aperture (1-6 mm), dimensions (up to 1.2 m x 30 m), mesh type, and edge style; manufacturers, distributors, and exporters in India offer tailored products and ready-to-use delivery.Q: How does optimized porosity improve the meshs performance?

A: The controlled porosity design allows efficient airflow while maintaining structural strength, which is essential for thermal insulation and supporting refractory materials under high-temperature conditions.Q: What are the main benefits of using this wire mesh?

A: Key benefits include high fire and corrosion resistance, customizable sizes, robust tensile strength, efficient airflow control, and suitability for both industrial and construction environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wire Mesh Category

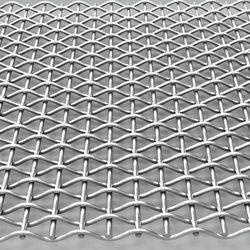

SS Crimped Wire Mesh

Price 50000 INR / Square Foot

Minimum Order Quantity : 100 Square Foots

Length : 30 m (Standard) or as per requirement

Color : Silver Metallic

Hole Shape : Other , Square or Rectangular

Paper Mill Wire Mesh

Price Range 40.00 - 400.00 INR / Square Foot

Minimum Order Quantity : 100 Square Foots

Length : 30 50 meters

Color : Silver

Hole Shape : Other , Rectangular

Plain Woven Wire Mesh

Price Range 40.00 - 400.00 INR / Square Foot

Minimum Order Quantity : 100 Square Foots

Length : 30 meters per roll or customized

Color : Silver, Green, Black (depending on coating)

Hole Shape : Other , Square

Plain Stainless Steel Wire Mesh

Price Range 40.00 - 400.00 INR / Square Foot

Minimum Order Quantity : 100 Square Foots

Length : 15 m 30 m rolls

Color : Silver

Hole Shape : Other , Square

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free