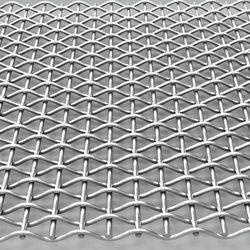

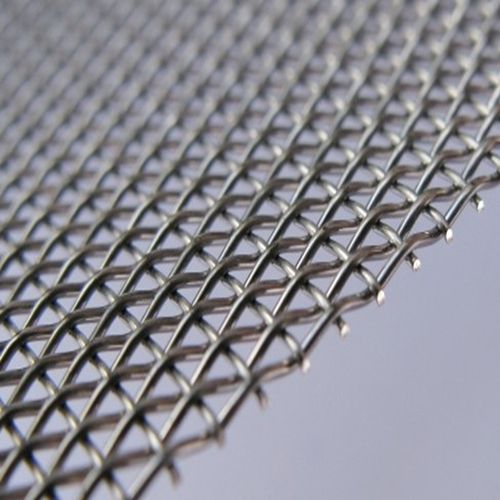

Plain Woven Wire Mesh

Plain Woven Wire Mesh Specification

- Length

- 30 meters per roll or customized

- Surface Treatment

- Galvanized, PVC coated, or plain

- Wire Gauge

- As per requirement (Standard range: 8 to 32 SWG)

- Hole Shape

- Square

- Aperture

- 0.1 mm to 25 mm

- Product Type

- Plain Woven Wire Mesh

- Mesh Type

- Plain weave

- Mesh Style

- Woven

- Material

- Stainless Steel, Mild Steel, Galvanized Iron

- Alloy

- Available in SS304, SS316, MS, GI

- Application

- Filtration, Sieving, Fencing, Industrial, Agricultural, Construction

- Dimensions

- Width: 0.5 m to 2 m, Length: 30 m or as required

- Wire Diameter

- 0.2 mm to 2.0 mm

- Weight

- Varies by specification (typically 10-30 kg per roll)

- Color

- Silver, Green, Black (depending on coating)

- Standard Packing

- Waterproof paper, Wooden case or as required

- Corrosion Resistance

- Excellent (stainless steel), Good (galvanized)

- Tensile Strength

- 350900 N/mm (depending on material)

- Open Area Percent

- 36% 86% (depending on mesh count and wire diameter)

- Edge Type

- Cut Edges or Selvage Edges

- Production Method

- Plain weave (over and under) construction

- Operating Temperature Resistance

- Up to 800C (for stainless steel)

Plain Woven Wire Mesh Trade Information

- Minimum Order Quantity

- 100 Square Foots

- Supply Ability

- 500 Square Foots Per Day

- Delivery Time

- 1-7 Days

About Plain Woven Wire Mesh

This specially designed Plain Woven Wire Mesh is used as integral part of vibrating screen system for sizing and screening of materials like stone, coal, sand and minerals. Developed as per international norms, this metal product is completely protected against impact and abrasion. Due to its advanced production technology, it can resist damaging effects of acid and alkali. Exceptional toughness level and unique strength are some of its main features. Moreover, its screening accuracy deserves praise. Quality of this product has been verified on the basis of its dimension, strength, resistant attributes, surface finish, raw material choice, longevity and service life. We are a distinguished trader and supplier of Plain Woven Wire Mesh that can be availed at reasonable price range.

Product Details

Color | Silver |

Material Grade | SS304 |

Brand | Safety Mesh |

Usage/Application | Construction |

Country of Origin | Made in India |

Width | 2 m |

Thickness | 50 mesh |

Packing Type | Roll |

Material | Stainless Steel |

Length | 15 m |

Versatile Design for Multiple Applications

Plain Woven Wire Mesh features a durable construction, making it indispensable for sectors like agriculture, construction, and industry. Whether you need robust fencing, precise filtration, or dependable sieving, this mesh delivers consistent performance. Customizable dimensions and coatings ensure it fits both lightweight and heavy-duty requirements.

Engineered for Strength and Longevity

With tensile strengths ranging from 350 to 900 N/mm and excellent temperature resistance (up to 800C with stainless steel), this mesh is designed to withstand rigorous use. Surface treatments such as galvanizing and PVC-coating further enhance resistance to corrosion and mechanical wear.

Tailored Packing and Reliable Supply

Each roll, typically 30 meters in length, is carefully packed in waterproof paper and secured in wooden cases. As a distributor, exporter, importer, manufacturer, and supplier based in India, we ensure prompt customization and secure delivery for all your project demands.

FAQs of Plain Woven Wire Mesh:

Q: How is plain woven wire mesh manufactured?

A: Plain woven wire mesh is produced using an over-and-under weaving method, with each wire alternately crossing, creating a robust, interlocked structure. Both cut edges and selvage edges can be provided for your specific application needs.Q: What are the main benefits of using plain woven wire mesh?

A: This mesh offers excellent strength, temperature resistance up to 800C (with stainless steel), and superior corrosion resistance, particularly when galvanized or PVC coated. Its ideal for applications requiring durability and adaptability.Q: When should I choose cut edges versus selvage edges for my mesh?

A: Cut edges are suitable for general uses where minimal handling is expected, while selvage edges provide greater durability and reduce fraying, making them preferable for demanding or repetitive-use environments.Q: Where can plain woven wire mesh be applied?

A: It is commonly used in filtration, sieving, fencing, and is extensively applied in industrial, agricultural, and construction projects due to its customizable specifications and reliability.Q: What is the process for customizing mesh size, wire diameter, and finish?

A: You can specify your required aperture (0.1 mm25 mm), wire diameter (0.2 mm2.0 mm), and surface finish (plain, galvanized, or PVC coated) during order placement. Rolls are usually supplied in 30-meter lengths, but custom sizes are available upon request.Q: How is the mesh typically packaged for shipping?

A: To ensure safety and prevent damage, the mesh is packed in waterproof paper and secured in wooden cases. Packaging can also be tailored as per specific requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wire Mesh Category

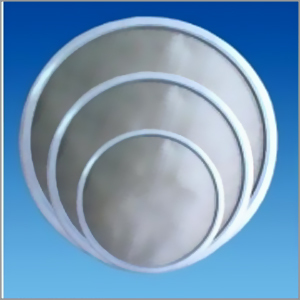

Pharma Wire Mesh

Price 400 INR / Square Foot

Minimum Order Quantity : 100 Square Foots

Mesh Style : Other , Plain Weave

Length : 1530 Meter (Standard Rolls)

Hole Shape : Other , Square

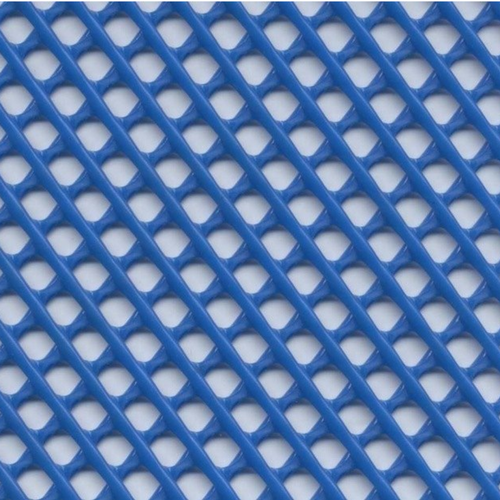

Plastic Wire Mesh

Price 14000 INR / Square Foot

Minimum Order Quantity : 100 Square Foots

Mesh Style : Other , Woven or Knitted

Length : 30 Meter Roll

Hole Shape : Other , Square

304/316 Plain Weave Stainless Steel Wire Mesh

Price Range 40.00 - 400.00 INR / Square Foot

Minimum Order Quantity : 100 Square Foots

Mesh Style : Other , Plain Weave

Length : 15 m, 30 m, or customized

Hole Shape : Other , Square

Super Duplex Stainless Steel Wire Mesh

Price 110 INR / Square Foot

Minimum Order Quantity : 100 Square Foots

Mesh Style : Other , Woven

Length : Variable

Hole Shape : Other , Square

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free