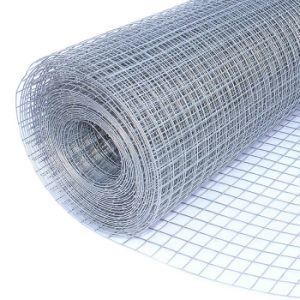

MS Weld Mesh

MS Weld Mesh Specification

- Wire Gauge

- 8 to 16 SWG

- Surface Treatment

- Black (Uncoated), Galvanized as required

- Aperture

- 12 mm to 150 mm

- Hole Shape

- Rectangular / Square

- Length

- Standard 6 m or custom as specified

- Product Type

- Welded Mesh Sheet

- Mesh Type

- MS Weld Mesh

- Mesh Style

- Welded Mesh

- Material

- Mild Steel

- Alloy

- Low Carbon Steel

- Application

- Fencing, Construction, Industrial, Agriculture

- Dimensions

- Width: 3 ft to 6 ft, Length: 6 ft to 12 ft

- Wire Diameter

- 1.5 mm to 5 mm

- Weight

- Variable as per size and wire gauge

- Color

- Silver, Black

MS Weld Mesh Trade Information

- Minimum Order Quantity

- 100 Square Foots

- Supply Ability

- 500 Square Foots Per Day

- Delivery Time

- 1-7 Days

About MS Weld Mesh

Multiple Applications and Benefits

MS Weld Mesh is widely used across fencing, construction, industrial, and agricultural projects due to its strength, versatility, and adaptability. Its welded joints provide structural stability, while its customizable dimensions and surface treatments ensure applicability in diverse environments, both indoor and outdoor. Galvanized variants offer enhanced resistance to rust, making them suitable for long-term installations.

Quality and Standard Compliance

Our weld mesh is crafted from premium low carbon mild steel and conforms to recognized standards such as IS 1566 and ASTM A185, depending on customer requirements. With wire gauges ranging from 8 to 16 SWG and tensile strength up to 550 MPa, it ensures durability and reliability for demanding projects. Available in a variety of finishes and colors, the mesh combines functionality with corrosion protection.

FAQs of MS Weld Mesh:

Q: How is MS Weld Mesh supplied to customers?

A: MS Weld Mesh is typically supplied in rolls with weights of 15 kg, 25 kg, or 50 kg, based on customer requirements. Both cut edge and folded edge options are available. Dimensions can be specified, with standard offerings ranging from 3 ft to 6 ft in width and 6 ft to 12 ft in length.Q: What surface treatments are available for corrosion resistance?

A: To enhance its lifespan, MS Weld Mesh can be surface-treated with a galvanized coating or specialized paint. While the standard mesh is uncoated (black), galvanized and painted versions provide greater protection against corrosion, especially for outdoor use.Q: When should I choose galvanized MS Weld Mesh over uncoated mesh?

A: Choosing galvanized MS Weld Mesh is recommended for outdoor applications or environments prone to moisture and chemicals, as the zinc coating offers better corrosion protection. For controlled indoor settings where corrosion is less likely, the uncoated (black) version may suffice.Q: Where can MS Weld Mesh be used?

A: This mesh is suitable for a range of uses, including perimeter fencing, reinforcements in construction, industrial partitioning, and agricultural enclosures. Its robust construction allows installation in both interior and exterior locations.Q: What is the process for ordering MS Weld Mesh with custom specifications?

A: Customers can specify wire gauge, mesh aperture size, length, width, and surface treatment requirements at the time of order. The mesh can be manufactured to conform to either IS 1566 or ASTM A185, based on project needs. Customization ensures the mesh meets specific application criteria.Q: What are the benefits of using MS Weld Mesh in construction and fencing?

A: MS Weld Mesh delivers superior strength, consistent aperture sizes, and reliable tensile properties, making it ideal for reinforcement and fencing tasks. Its corrosion resistance (when treated) ensures long-term durability, and the welded design simplifies installation and handling.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Welded Mesh Category

GI Welded Mesh

Price Range 40.00 - 400.00 INR / Square Foot

Minimum Order Quantity : 100 Square Foots

Wire Diameter : 2.5 mm

Aperture : 50 mm x 50 mm

Mesh Style : Welded Mesh

Dimensions : 1 m x 25 m (standard roll size)

Mild Steel Weld Mesh

Price Range 40.00 - 400.00 INR / Square Foot

Minimum Order Quantity : 100 Square Foots

Wire Diameter : 0.56 mm to 4.06 mm

Aperture : 12 mm x 12 mm ~ 100 mm x 100 mm

Mesh Style : Welded Mesh

Dimensions : Width: 0.5 m to 2.5 m or customized

Spring Steel Wire Mesh

Price Range 40.00 - 400.00 INR / Square Foot

Minimum Order Quantity : 100 Square Foots

Wire Diameter : 0.5 mm 2.5 mm

Aperture : 0.5 mm to 20 mm

Mesh Style : Other , Woven

Dimensions : Standard and customizable (e.g. 1 x 5 m, 1.2 x 2.4 m)

Stainless Steel Welded mesh

Price Range 40.00 - 400.00 INR / Square Foot

Minimum Order Quantity : 100 Square Foots

Wire Diameter : 0.5 mm to 2.5 mm

Aperture : 12.5 mm to 50 mm

Mesh Style : Welded Mesh

Dimensions : customizable, standard width: 900 mm 2000 mm

Send Inquiry

Send Inquiry