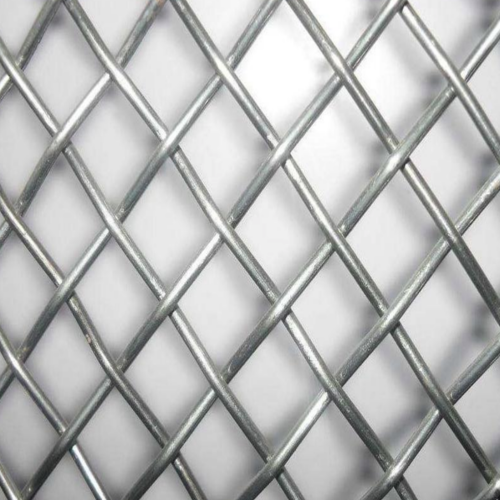

Stainless Steel Wire Mesh

Stainless Steel Wire Mesh Specification

- Hole Shape

- Square

- Wire Gauge

- 2-12 Gauge

- Length

- 15-30 Meter

- Aperture

- 0.5-3 mm

- Surface Treatment

- Galvanized

- Product Type

- Wire Mesh

- Mesh Type

- Wire Mesh

- Mesh Style

- Woven Mesh

- Material

- Stainless Steel

- Alloy

- SS304/SS316

- Application

- Industrial, Construction, Filtration

- Dimensions

- Customizable

- Wire Diameter

- 0.5-2 mm

- Weight

- Standard

- Color

- Silver

- Minimum Order Quantity

- 10 Square Meter

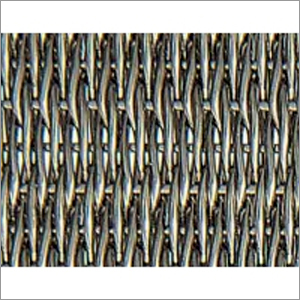

- Weave Type

- Plain weave, Twill weave

- Edge Type

- Plain Edge, Lock Edge

- Temperature Resistance

- High

- Usage

- Fencing, Screening, Grading

- Corrosion Resistance

- Excellent

- Packing Type

- Rolls

- MOQ

- As per requirement

Stainless Steel Wire Mesh Trade Information

- Minimum Order Quantity

- 100 Square Foots

- Supply Ability

- 500 Square Foots Per Day

- Delivery Time

- 1-7 Days

About Stainless Steel Wire Mesh

Application of Stainless Steel Wire Mesh can be noticed in chemical processing, pharmaceutical and also in food processing fields. Provided mesh is used for screening and sorting of gas, liquid and solid materials. It is also utilized for designing walkways and working platform. Offered mesh is completely protected against rust, acid, high temperature and wear. Generally, 304L/304/316L grade steel is used to fabricate such product. Offered mesh can be availed with spray painted or powder coated or PVDF treated or anodized surface finish based options. Quality of this product has been verified on the basis of its material choice, surface finish, strength, longevity, hole diameter etc. We are a reliable trader and supplier of standard grade Stainless Steel Wire Mesh.

Product Details

Length | 15 m, 30 m |

Material | SS |

Material Grade | SS304, SS316 |

Brand | Safety Mesh |

Width | 1 m, 3 feet, 4 feet |

SWG | 12 to 50 |

Mesh | 2 to 500 |

Versatile Mesh Configurations

Choose from plain or twill weave and select plain or lock edges to meet specific application needs. With customizable dimensions and wire diameters between 0.5-2 mm, this wire mesh fits a wide range of industrial functions, ensuring optimal performance in screening, fencing, and grading.

Superior Durability and Resistance

Manufactured using high-quality SS304 or SS316 stainless steel, the mesh exhibits excellent resistance to corrosion and can withstand high temperatures. Its galvanized surface treatment further enhances longevity, making it particularly suitable for both harsh environments and long-term use.

FAQs of Stainless Steel Wire Mesh:

Q: How does the stainless steel wire mesh perform in high-corrosion environments?

A: The mesh is crafted from SS304 or SS316 stainless steel and features a galvanized finish, providing exceptional resistance to corrosion. This makes it highly suitable for applications where exposure to moisture or chemicals is frequent, such as filtration and industrial processes.Q: What are the common uses of plain and twill weave types in wire mesh?

A: Plain weave offers uniform strength and is generally used for basic screening and fencing, while twill weave enables a tighter mesh and higher strength, ideal for demanding filtration or grading tasks. The choice depends on the mechanical requirements of your specific application.Q: When should I opt for a lock edge versus a plain edge for my wire mesh?

A: Lock edges provide enhanced stability and prevent unraveling, which is valuable in heavy-duty or high-vibration environments. Plain edges are suitable for general applications where the mesh will not be exposed to significant mechanical stress.Q: Where can this stainless steel wire mesh be installed effectively?

A: This mesh is suitable for use in industrial, construction, and filtration settings. It can be installed in fencing, screening, grading frameworks, and machinery, offering adaptability thanks to customizable dimensions and wire gauges.Q: What is the process for ordering customized dimensions or mesh configurations?

A: To order custom sizes or specific weave types, simply indicate your requirements for length, width, aperture shape or size, edge type, and alloy preference. Our team will assist in providing a tailored solution based on your applications demands.Q: How can I benefit from the meshs high temperature and corrosion resistance?

A: Utilizing this mesh ensures lasting performance in extreme conditions, reducing maintenance costs and downtime. Its high durability makes it a reliable choice for applications in challenging environments where standard wire mesh would degrade quickly.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wire Mesh Category

Filter Wire Mesh

Price 13000 INR / Square Foot

Minimum Order Quantity : 100 Square Foots

Surface Treatment : Other, Galvanized, PVC coated

Mesh Style : Other , Woven and Welded

Aperture : 1 mm 20 mm

Steel Wire Mesh

Price Range 40.00 - 400.00 INR / Square Foot

Minimum Order Quantity : 100 Square Foots

Surface Treatment : Other, Galvanized / PVC Coated

Mesh Style : Other , Welded / Woven

Aperture : 5 mm to 50 mm

Paper Mill Wire Mesh

Price Range 40.00 - 400.00 INR / Square Foot

Minimum Order Quantity : 100 Square Foots

Surface Treatment : Galvanized

Mesh Style : Other , Woven / Welded

Aperture : 2mm 8mm

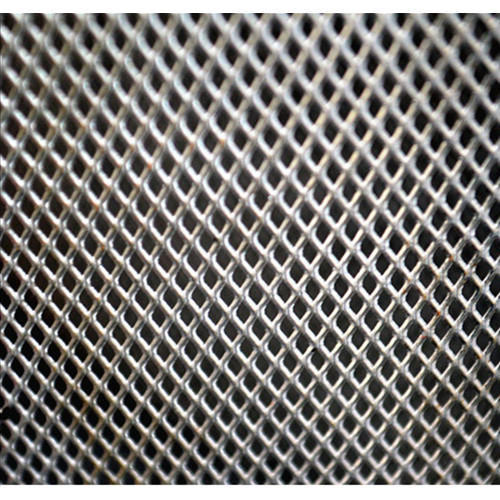

Diamond Wire Mesh

Price Range 40.00 - 400.00 INR / Square Foot

Minimum Order Quantity : 100 Square Foots

Surface Treatment : Other, Galvanized, PVC Coated

Mesh Style : Other , Expanded or Welded

Aperture : 25mm to 100mm

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free